SHREDDING/ SORTING

“The same key will not open all the locks”. There are hundreds of different types of EEE Scraps being generated along with the changes in the fast growing technology. We need to think and design a right key for the right type of material shredding and sorting.

VANS CHEMISTRY able to help the clients in selecting the right, cost effective, efficient shredding technology. Selection of right machines and process depends on the following factors,

- Material availability

- Material quality

- Material flow

- Capacity

- Output quality

- Scalability

- Wear and Tear

- Energy consumption

- Man power

- Environmental friendly

- Traceability and Mass balance

- Profitability

- Return on investment

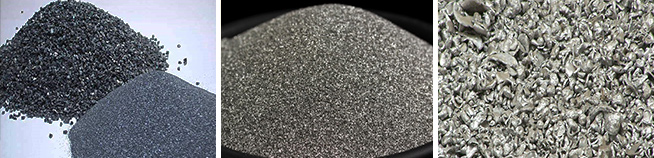

Shredders and Granulators

Shredders and Granulators

- Shredders help to reduce the size and volume of various types of EEE Scrap. The selection depends on quality of input material, output capacity and required output size.

Sorting / Separators

- Sorting machines helps to separate various types of metal fractions, plastics etc., The selection of sorting/ separation systems will depends on the required purity of output fractions.

Online Samplers

- Online sampling system helps to draw homogeneous qualitative sample at regular intervals. The sample determines the precise quality and value of EEE scraps.

Dust collection and bag filter system

- The key challenge in mechanical operation is to prevent particulate / dust exposure and noise control. We can design completely enclosed environmental friendly system. So the particulates/ dust generated shall be diverted to multiple cyclones followed by bag filter system.

Data wiping, degaussing and destruction equipments

- The information and communication technology has resulted a huge threat on data's and intellectual property. We ,VANS CHEMISTRY gives highest importance to develop a customized equipment and technology, so as any clients data and IP shall be protected in an environmental friendly way.

For more information, kindly reach us through the link below: